Eravision Track and trace solution Main features

1. Easy And Intuitive Operator Interface: A single, user-friendly operator interface simplifies the machine setup and operation, reduces human error, and machine setup times while increasing overall equipment efficiency.

2.Compliance With Global Serialization Regulations.

3. Accurate Printing and Verification at High Speed: the highly accurate printing and verification technology guarantees the lowest possible product reject ratio.

4. Stable transfer positioning of folding boxes and guided transport for safe and optimal printing and reading results.

5. Industrial Large 15” with touchscreen display and intuitive control menu.

6. High throughput rate of 300 pcs/min is standard.

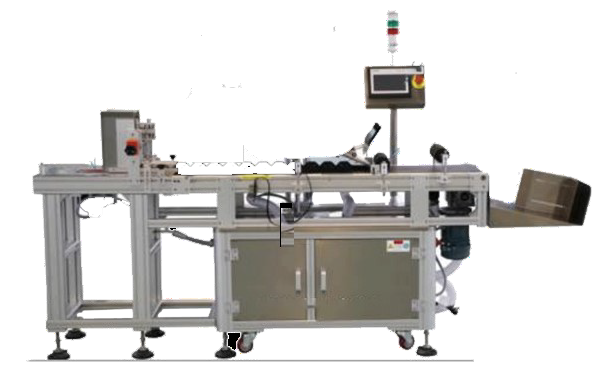

7. Space saving design facilitates integration in existing lines.

8. Rejection of faulty products into a lockable rejection bin.

9. Compact, high-tech, multi-functional unit for optimal productivity.

10. automatic running, the alarms & interlocks managing and continuous monitoring and reporting.

Technical details

Serialization report with status report for the release reject quantities.

· Audit Trail Report

· Alarm Reports

· Parameters for each Stage

· Data Security: CFR 21 part 11

· Data backup. Machine setting and recipe will be applicable on external server or mass storage.

· Internal storage for cycles up to 200 GB or more.

•Grade A up to 600 dpi Resolution

•Print speed 40m/min.

•Connects up to two print heads.

•Nozzle warming, auto-jet and self-cleaning capabilities.

• Nozzle status checking.

· Interface GigE

· Resolution 2448x2048

· Pixel Bit Depth 8bit, 10bit

· Shutter Type Global Shutter

Compressed air Approx. 6 bar.